Polished Concrete vs. Epoxy Resin: A Showdown for Warehouses:

High Traffic Warehouses Flooring Solutions: Choosing the Right Floor (Lime Flooring)

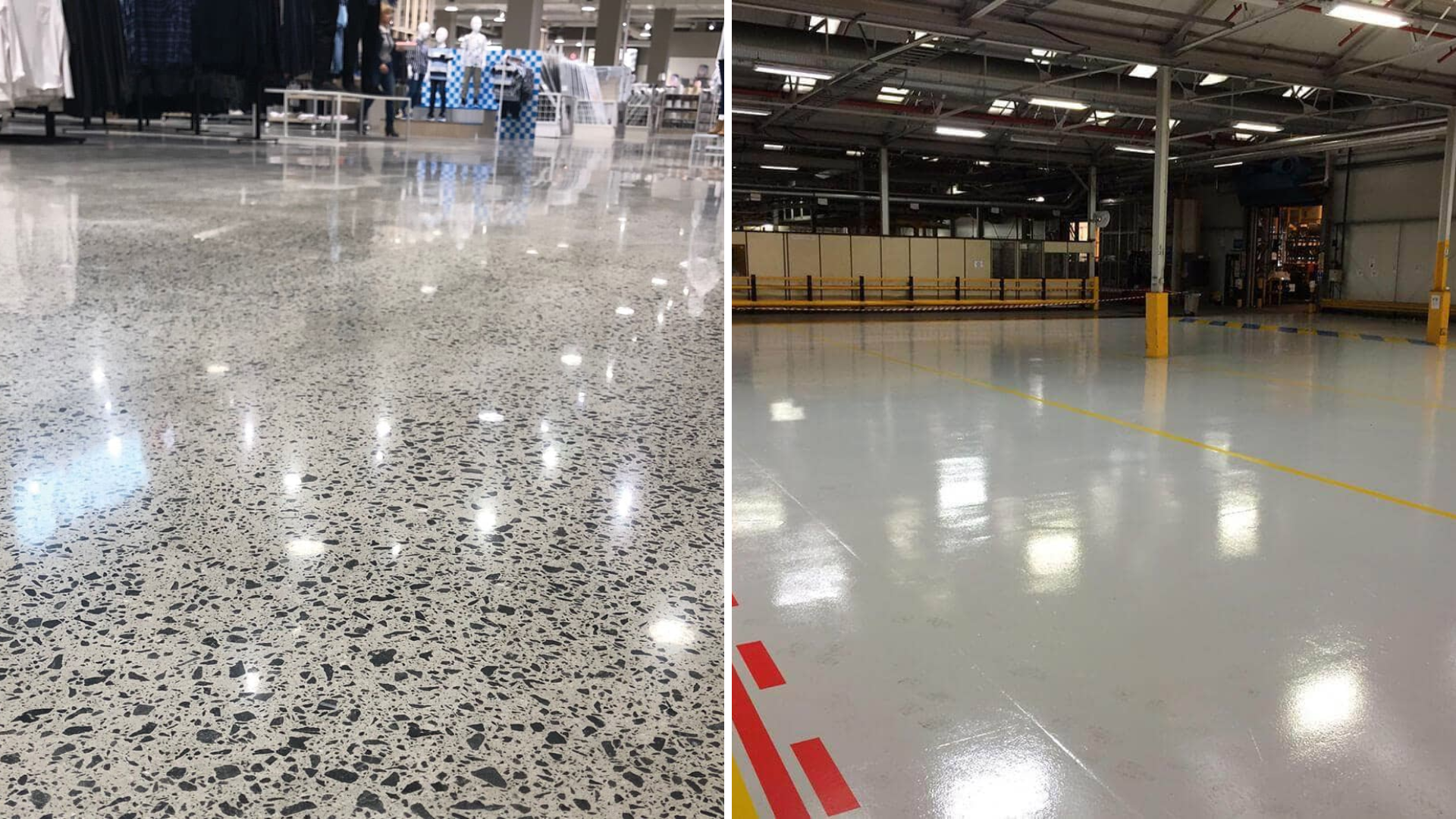

Here at Lime Flooring, we're experts in Commercial Flooring Solutions, with a focus on high-traffic environments across the UK. When it comes to warehouses, the constant movement of heavy machinery, forklift traffic, and potential for spills means choosing the right flooring is crucial. Two popular options are polished concrete and epoxy resin, but which one reigns supreme? We'll delve into the pros and cons of each to help you make the best decision for your warehouse.

Unveiling the Power of Polished Concrete

Polished concrete is exactly what it sounds like – concrete treated and polished to create a smooth, incredibly durable surface. This makes it a perfect choice for warehouses. Here's why:

- Built to Last: Lime Flooring uses top-of-the-line techniques to create a high-strength, long-lasting concrete floor. It can withstand heavy equipment traffic, impact from dropped objects, and years of wear and tear without showing significant signs of damage.

- Low Maintenance Champion: Polished concrete is a cost-effective option in the long run. Unlike other materials, it doesn't require waxing, buffing, or frequent replacements. Regular sweeping and occasional mopping with a PH-neutral cleaner are all it takes to keep your polished concrete floor looking its best.

- Sustainable Choice: Polished concrete uses less material compared to other flooring options. Additionally, its low maintenance requirements translate to less cleaning product usage, making it a more environmentally friendly solution.

Epoxy Resin – A Strong Contender, But with Caveats

Epoxy resin flooring is another popular choice for warehouses, offering its own set of advantages:

- Chemical Warfare Defense: Epoxy resin is known for its excellent chemical resistance. This makes it ideal for warehouses where spills are a concern, such as those storing paints, cleaning products, or other chemicals.

- Design Your Dream Floor: Epoxy resin allows for a bit more customization compared to polished concrete. You can choose from a variety of colours to enhance your warehouse's aesthetics or even incorporate design elements like directional markings for improved safety.

However, it's important to consider some limitations of epoxy resin before making a final decision:

- Susceptible to Battle Scars: While it boasts chemical resistance, epoxy resin can chip, crack, or peel under heavy equipment traffic or impact. This can lead to uneven surfaces and potential safety hazards over time.

- Slip and Slide Concerns: Epoxy resin can become slippery, especially when wet or worn. This could pose a risk for workers in warehouses with high forklift traffic. While there are anti-slip options available, they may require more frequent reapplication compared to the inherent slip resistance of polished concrete.

- Maintenance on Repeat: Epoxy resin may require more frequent maintenance compared to polished concrete. Depending on the wear and tear, you might need to recoat the floor every few years, which adds to the overall cost.

Lime Flooring's Polished Concrete – The Warehouse Champion?

After a thorough examination, polished concrete emerges as a strong contender for high-traffic warehouse environments. Its impressive durability, low maintenance needs, and long lifespan make it a cost-effective solution in the long run. Here at Lime Flooring, we go beyond just providing polished concrete; we offer expert installation, aftercare services to maintain your floor's shine, and warranties for peace of mind.

Conclusion

Choosing the right flooring for your warehouse depends on your specific needs and priorities. Polished concrete offers a compelling combination of durability, low maintenance, and cost-effectiveness for warehouses with high foot traffic and heavy machinery.

We encourage you to explore our projects page to see examples of our work in various warehouse settings. Lime Flooring is a Husqvarna Superfloor™ accredited contractor, ensuring you receive the highest quality polished concrete solution for your warehouse.

Ready to discuss your warehouse flooring needs? Visit our Contact Page or browse our News page for more information on how Lime Flooring can help you create a durable, functional, and safe environment for your business.

This article was produced by

SEO Local Services.

Get in Touch